Do you want to respond quicker to quotation requests? Do you want to lower the necessary administrative steps to estimating and quoting?

If so, you'll know that it's difficult because sheet metal estimating and quoting can be a time-consuming activity that will also determine your profitability. You can't really cut corners there.

So, what do you do? Many businesses have found success by using automated quoting and estimation software to process requests quickly and accurately.

However, there are a few things you should know before you buy and implement any quoting software to ensure your productivity will increase.

This post will tell you what you need to know to make sure you select a sheet metal estimation and quoting software that will let you successfully automate your processes.

- Introduction: The Problems of Quoting in 2022-2023

- There is more pressure on sales than ever before

- The Solution: Sheet Metal Quoting Software

- How to Choose the Right Sheet Metal Quote Software for Your Business Needs?

- 5 Types of Sheet Metal Quoting Systems You Can Find in the Market

- #1: Computer-Aided Designing (CAD) software Add-ons

- #2: Computer Aided Machining (CAM) Software (as an Add-On)

- #3: Dedicated On Premise Quoting Software

- #4: Online Quoting Software (Cloud-Based)

- #5: Custom solutions and ERP

- Questions? Let us help you with your software selection!

- Tips for using Sheet Metal Quoting Software for Better Results

- Determine your shop rates

- Setting up your routings and articles

- Web portal

- How does it come together in your smart factory?

- Conclusion: Pick a software that matches your needs and budget

Introduction: The Challenges of Quoting

Sheet Metal fabrication is a tough and risky business to remain competitive. Manufacturing processes can be underestimated, leading to high-costs and therefore making it hard to remain profitable.

The handling of RFQs is a tedious manual task that often requires an expensive sales force with deep understanding of the industry. This often ends up on the owner's shoulders, who have to make the long hours to do the work.

Of course, many companies have made attempts to automate the work with some spreadsheet or calculation template, but more often than not it leads to complicated custom solutions (looking at you, Excel!).

Finding the skills and experience to know how to quote is getting harder every day. Not to mention that hiring more staff to quote is making your products more expensive, which is making it harder to actually win the projects and eats away at margins.

Quotes are prone to mistakes and prices may also vary between employees, which can result in inconsistent output. This may be due to different work methods.

Due to the amount of work it can take and the need for accuracy, business owners and estimators often find themselves working on quotations requests until late at night. This, while they could and should be focussing on strategic matters of the business instead. When multiple projects are going on at the same time, this can cause mistakes or completely forgotten projects.

So, quoting is a very challenging part of the business. Unfortunately, there is no good news yet because it will get worse in the near term. Here's why:

There is more pressure on sales than ever before

The competitive markets of today require an understanding of cost structures for an adequate pricing strategy. And the customer is no longer willing to wait for long periods for their requests.

Just shipping a few parts here and there won't keep you profitable anymore. Not only have margins shrunk, but also the requirements for projects have become more complex. There has been a decrease in series and an increase in variety.

Many requests for quotations (RFQ) contain many additional requirements. If you're estimating sheet metal parts, including cutting, bending, roll forming, punching, welding, and more, you'll quickly realize that doing all this manually is an impossible task to take on. Especially when you want to grow your business in the years ahead.

Finally: material pricing is fluctuating rapidly. Re-calculating entire projects each time is hard without a good system for this. So, it should be able to update past pricing projects easily, without having to create the quotation from scratch again.

And did we already mention that low wage countries are getting better and better to deliver the same products every day?

The Solution: Sheet Metal Quoting Software

The key to winning new business is a quick response to customer requests for a quote. Sheet metal quoting software is a dedicated program that serves this purpose.

It's a fabrication cost estimating and quoting software for sheet metal parts. It quickly generates cost estimates of fabricated parts With a good solution, users can turn around cost estimates for fabricated parts and assemblies in minutes rather than hours (or even days).

Many types of solutions are out there, but they all share one common trait: it all starts with a drawing and / or model. If there is no model, the software sometimes can generate a model based on a provided draft or has a built-in CAD-software to design parts quickly.

With the model, the software then determine the working steps according to the recognized features in the model. In a 2D CAD-model, this is often based on a tool path and for 3D models based on distinct shapes, such as bends and tapped holes.

The process usually starts with one or more files being imported into the software. For 3D models, the sheet metal is unfolded first, usually by internal CAD-software. The user then selects the necessary materials and enters any additional required working steps.

The software then determines the required tool paths and calculates how long these would take. On top of this, set-up times and run times are configured.

Lastly, margins are added to the materials and the project. Combining these with the time and the margin results in a finished quote that can then be sent to the customer.

How to Choose the Right Sheet Metal Quote Software for Your Business Needs?

If you're looking for sheet metal quoting software, the best way to ensure you end up with something that allows you to respond quicker and more accurately is to look for these things:

- Make sure your sheet metal quoting software integrates with your other software systems, such as ERP. If it doesn't, you'll have trouble processing these quotations when they become a project.

- Ensure your estimations are based on actual machining data, such as cutting tables, so you can calculate accurately. Especially for larger projects, the time needs to be right.

- Any good software should let you configure additional work steps such as post-processing, packaging, and shipping. This is important because otherwise you'll have to make the final quote in another software system, which goes against the idea of having a software for this in the first place.

While not necessary, some great bonus features of a great quoting solution are the ability to open the software to your customers as a web shop, checking for manufacturability and support for many file types like .STEP files, DXF, DWG, and more.

5 Types of Sheet Metal Quoting Systems You Can Find in the Market

Now that you know what to look for in a software, let’s examine a couple of types of programs you could buy and how they work.

#1: Computer-Aided Designing (CAD) software Add-ons

As an engineer/draftsman, you’re familiar with designing 3D and 2D Parts. However, many people don’t realize that most CAD-software comes with powerful estimating options, and can be extended by creating custom add-ons and plugins.

The way how this works, is that by opening a model, the software will analyze the features, volumes, and contours and then makes an estimation of the costs.

For having a quick glance of the pricing of a product, this can be very useful. For more detailed estimations, there are also software add-ons that combine both the CAD-software functionalities and add extra layers of information.

By working within your CAD-software, engineers can save time and often already are well familiar with the systems. However, making a final quote can be tricky since margins need to be determined and most CAD-software don’t allow creating sheet lay-outs/nestings.

So, the accuracy will be quite limited in most cases.

Pros

- Quick price indications

- Work from your trusted CAD software

- Ability configure yourself

Cons

- Often less accuracy due to missing nestings

- Requires a modern CAD-software and knowledge of this

- Limits quoting only to qualified engineers

Examples of CAD-based Quoting Software

Examples:

- Ansys Spaceclaim

- SolidWorks costing module

- Autodesk Inventor (through iLogic)

- SPI SheetMetal Calculator for Inventor and SolidWorks

- Yobman for space claim (see video demo below):

#2: Computer Aided Machining (CAM) Software (as an Add-On)

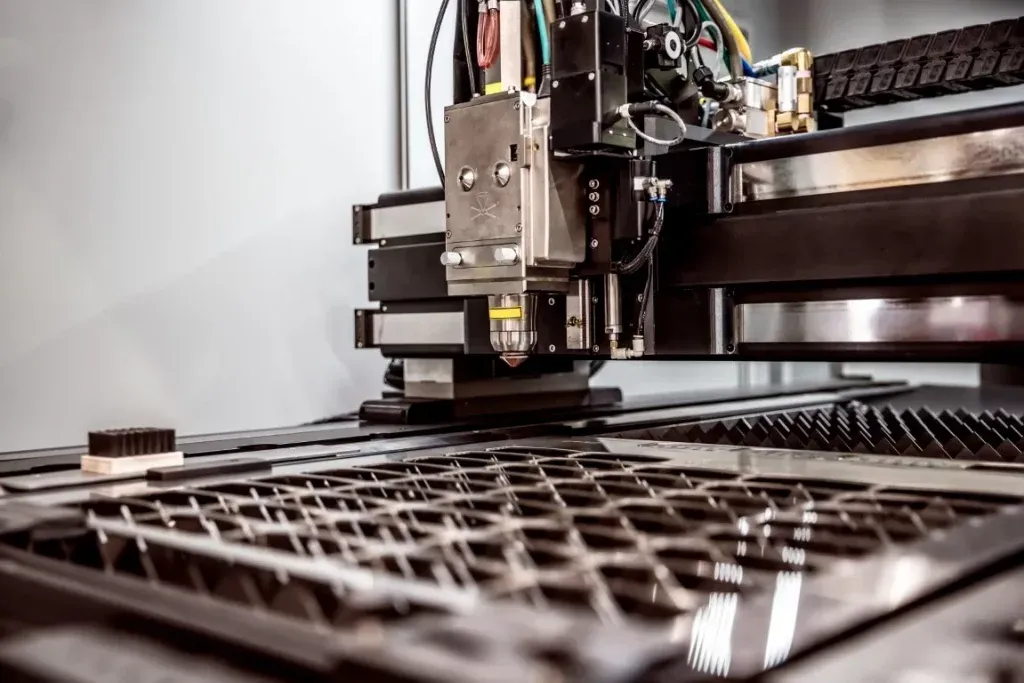

If you’re an owner of a sheet metal fabrication business, you’re most probably familiar with CAM software to generate the CNC code for your machines. This is based on tables that contain the machine parameters. Typically, CAM-software is focussed on a specific operation, such as laser cutting, water cutting or plasma cutting.

There are many businesses that quote by using the set-up plans of the machines as a guideline for the total time and material, which they calculate into a final price. However, to make these estimations requires a lot of upfront work to generate these set-up plans. And since not every quote becomes an order, it can be quite a big waste of time.

Furthermore, by just using the CAM-software you’re only focussed on one processing step at a time, once extra operations are necessary of multiple material types etc. It still requires a lot of handwork, and you’ll probably end up with an overly complex Excel sheet that cannot integrate to the rest of your business, with all the problems that come with that.

The solution: An add-on on top of your CAM-software. In this way, you’re still estimating based on machine tables, however now you can add multiple extra working steps and then export the quotation to your customer directly from the software, without having to retype everything or having to fiddle around with Excel.

Pros

- Often can be quickly implemented if you already have CAM of the same brand

- Good process flow with your current machines

- Production times of sheet metal cutting processes often accurate

Cons

- Requires a lot of time upfront from sales engineer to prepare files

- Integration with other systems such as ERP is often complicated

- Only suitable for simpler sheet metal job shops, less suitable for welding etc.

Examples of CAM-based Quoting Software

#3: Dedicated On Premise Quoting Software

Very similar to CAM software (!), these kinds of pieces of software are more agnostic to brands and operations. They are designed to quote many working steps and should provide an all-in-one solution (not only sheet cutting) regardless of what kind of machining you're doing. The software packages are extensively customizable and configurable.

Pros

- Works with almost any brand

- Quickly to implement due to templates

- Lots of customization options

- Affordable

Cons

- Integrations are usually challenging

- Most solution we could find are a bit dated (if you have a modern one, shoot us a message!)

- On premise, meaning licensing and network can have issues

Examples of On-Premise Quoting Software

#4: Online Quoting Software (Cloud-Based)

There are many ways that online quoting software can help a metalworking company increase sales. This type of software saves time by eliminating errors and providing accurate quotes to customers immediately.

Online quoting software also allows customers to get quotes for any custom orders without having to wait on a sales rep to answer. Often, they're capable of placing the order directly online with you.

For metal fabricators, this means that a customer can upload their 2D and 3D-CAD models, combined with the technical product requirements, where a CAM software system analyses the requirements and calculates the price of the product. The price is based on the configuration of the product.

The technique of quoting online has become a popular way to attract new customers and to renew business for metalworking companies.

Pros

- The most modern solution

- Highly flexible

- Often the most accurate quotations

- Most time saving

Cons

- Significant investment

- Requires education and training

- Take some time to set up

Examples of Online Quoting Software

Examples:

Rhodium24 / QuotationFactory:

Paperless Parts:

SecturaFab:

#5: Custom solutions and ERP

There are many other combinations possible, for example an integration of your ERP system and quotation software or one of the previously mentioned examples. Almost all examples from above should be easily to integrate with an ERP system.

We are also aware that there are ERP providers that have their own quoting solutions within their systems. It can work and be an efficient way to work, but to process modern requests based on 2D- and 3D- models, we recommend a dedicated solution.

In our experience, these quotation solutions are limited or rely on external tools (like the ones above). If there are no external tools, in our experience, accuracy and process efficiency can fall behind.

For more information on this topic, please read the Top 10 ERP Systems article.

Questions? Let us help you with your software selection!

Are you not sure which software is best for you? Get started with a free introduction call, and we'll help you determine what kind of software you need. We're 100% independent and brand agnostic.

Tips for using Sheet Metal Quoting Software for Better Results

Determine your shop rates

To get started, you’ll need to answer the key question: What is your rate? This rate can be hourly, based on the week’s workload, how large the material batch is, and you probably will have some fixed administrative costs. The methods to calculate this is extensive, but a good article about this would be this article.

Deciding on your costing methods

There are a few ways how you can calculate your production costs. A great guide on this is written by DALLAN in the following article.

In summary, the fundamentals will determine on how you consider your business and how many value added services you’re brining. For example, if you can deliver quickly or provide extra certifications, your rate can, of course, be much higher than a competitor that takes weeks and lets you do all the paperwork yourself.

Setting up your routings and articles

If you’re quoting, you could at the same time execute some work preparation tasks. If done correctly, this can result into predetermined routings, articles that can be then used later in production once it becomes a sales order. This can be a massive time saver.

Web portal

If your quoting is going automated and accurately, why not let your customers enter the RFQ’s themselves? In that way, they're able to request projects with you 24/7 and as many as they like.

A good web shop play a vital role in the customer journey. They are the first point of contact for new customers, and they provide information about the company and its services. Hence, they must be set up in a way that provides an attractive and easy to navigate experience for customers.

How does it come together in your smart factory?

Depending on the solution chosen, you could go as far as to say that the online portal results in direct programs at your machine, without the need of any employee to enter the orders in the system. In this case, we're reaching a fully automated factory, or a smart factory.

Conclusion: Pick a software that matches your needs and budget

Now that you know everything there is about sheet metal quoting software with numerous great examples, you're ready to automate your estimation and quoting processes without worrying if it’s a good idea for you.

The answer is simple on that one: to remain competitive, it's a must. Plus, there are plenty of options out there. But which one to pick?

We’re here to help. Get started with a free introduction call, and we'll help you determine what kind of software you need.